Couplings

Boreline is supplied with fully re-usable 316 grade Stainless Steel couplings each comprising a body and two outer fastening clamps. The coupling body incorporates a BSP male threaded connection for attachment to the pump / headplate & two ribs over which the hose fits and the clamps are tightened – the two fastening clamps being split into three equal parts. ( Other coupling materials may be available on request.) This also applies to the cost-effective Plastic GRN Couplings developed specifically for the Boreline.

Stainless Steel Coupling

GRN Polymer Couplings

Drainer Systems

Break-Off Plug / Drainer System ( 2” and above )

Break-Off Plug / Drainer System ( 2” and above )

In order to minimise its weight, the riser should be empty when lifting the pump for inspection. This is often done by drilling the pump’s non-return valve so that the water drains back at a controlled rate, the alternative is to use the Break Off Plug system.

The Break-Off System has been developed to avoid this : the non-return valve is retained intact and a hollow stainless steel drainer plug is fitted across the lower Boreline coupling. This is then broken off at a weak point, when necessary, with a special ‘torpedo’ lowered down the hose.

The Break-Off System has been developed to avoid this : the non-return valve is retained intact and a hollow stainless steel drainer plug is fitted across the lower Boreline coupling. This is then broken off at a weak point, when necessary, with a special ‘torpedo’ lowered down the hose.

For 3” to the 8” Boreline the Break-Off Plug is mounted directly into the side of a specially modified lower Boreline coupling between the pump and riser. For 2” coupling a separate plug adaptor is fitted between the ( standard ) lower coupling and the pump discharge. A ‘torpedo’ is used to break the plug to allow water to drain from the riser for easier clamping during pump removal. Break-Off Plug systems must be requested at the time of ordering – they are not available for smaller sizes where the weight to be lifted doesn’t justify.

Break-Off Plug Installation

After attaching the coupling to the submersible pump, screw the correct size of Break-Off Plug into the tapped hole in the side of the coupling body. PTFE tape should be used for a seal and the plug tightened to the correct torque setting of 20Nm.

For 2” Boreline the Break-Off Plug is fitted into an adaptor, screwed into the pump discharge below the normal coupling.

Boreline riser retrieval where the Break-Off Plug system is used : –

1. Remove the discharge piping from the wellhead to give access to the inside of the rising main.

2. Select the correct torpedo size to pass thorough the Boreline Couplings and check that there are no sharp edges which could damage the Boreline hose’ lining.

3. Secure a suitable rope or cable to the top of the torpedo to allow it to be lowered down inside the riser.

4. Lower the torpedo to rest on the Break-Off Plug at the bottom of the riser and the rope becomes slack.

5. Raise the torpedo two metre and then allow to drop freely onto the plug.

6. The water will now drain down to the standing water level in the well and you can commence lifting the pump. The water will continue to drain until the pump is above the water level so allow sufficient time for this before securing lifting clamps or removing the Boreline over a roller.

7. Once the pump has been removed from the well, the old Break-Off Plug must be extracted from the coupling ( or 2’’ adaptor ) and a new one fitted prior to reinstallation.

Lifting Clamps

The Boreline lifting clamps are required to hold the Boreline during installation and removal. The have been designed and tested by Hose Manufacturers for use on the Boreline. Two clamps are required for each installation. They are available in three sizes to suit the whole Boreline Range. From 1” to 8”. Boreline Clamp Light Duty LC1 : 1″ to 2″ Boreline Clamp Medium Duty LC2: 2″ to 5″ Boreline Clamp Heavy Duty LC3: 6″ to 8″. Special clamps can be designed and manufactured on request.

The Boreline lifting clamps are required to hold the Boreline during installation and removal. The have been designed and tested by Hose Manufacturers for use on the Boreline. Two clamps are required for each installation. They are available in three sizes to suit the whole Boreline Range. From 1” to 8”. Boreline Clamp Light Duty LC1 : 1″ to 2″ Boreline Clamp Medium Duty LC2: 2″ to 5″ Boreline Clamp Heavy Duty LC3: 6″ to 8″. Special clamps can be designed and manufactured on request.

Installation Rollers

BORELINE INSTALLATION PROCEDURE USING A VEHICLE

A tripod or crane will be required to lift the pump into the borehole. If a tripod is used it should be positioned directly above the borehole high enough to allow the pump and clamp to be raised into the borehole.

A tripod or crane will be required to lift the pump into the borehole. If a tripod is used it should be positioned directly above the borehole high enough to allow the pump and clamp to be raised into the borehole.

Connect the Boreline coupling to the pump discharge or check-valve, or non-return valve and then the Boreline riser to the coupling.

Unroll the Boreline riser along the ground. Lay the power cable next to the riser along the length.

Connect the power cable to the pump motor. (This should only be carried out by a qualified electrician). Use the Boreline cable straps to tie the power cable to the riser at the recommended intervals. (Remember to snake the power cable along the length allowing approximately 5% slack). See fitting the power cable.

Clamp the Boreline riser only (not the power cable) using the Boreline clamps approximately 500mm above the pump.

Lift the pump using the clamp and lower it into the borehole until the clamp rests on the well head. Move the rolling wheel over the borehole ensuring that it is centrally positioned and secured. (An unsecured roller can move and cause injury to the operator).

Lift the Boreline riser over the rolling wheel with the power cable fastened and positioned.

Attach the second Boreline clamp to the other end of the riser and secure it to the installation vehicle. Reverse the vehicle so that the vehicle now takes the weight of the pump. Remove the first clamp. (The full load will now be taken by the vehicle and rolling wheel).

Drive the vehicle slowly forward allowing the pump and riser to be lowered into the borehole. Joiners, couplings and clamps must not pass over the rolling wheel.

When the vehicle is close to the rolling wheel, clamp the riser above the wellhead. Lower the riser slightly so that this clamp now rests on the wellhead. Remove the clamp from the vehicle.

Attach the second Boreline coupling and head works to the end of the riser.

Raise the head works using the tripod or crane, remove the clamp and lower the assembly onto the borehole.

BORELINE RETRIEVAL PROCEDURE USING A VEHICLE

Stop the pump, if a 6mm hole has been drilled into the check valve, allow the water to drain down (10s per foot) to the static water level.

Disconnect the electrical supply and discharge pipe-work.

Lift the Boreline out of the borehole and clamp the riser with the Boreline clamps.

Place the rolling wheel against the borehole. Fold the Boreline over the rolling wheel and attach it to the vehicle. Drive the vehicle away from the borehole so that it takes the weight of the riser and pump and remove the clamp.

Drive the vehicle slowly away from the borehole removing the Boreline and pump.

As the pump approaches the top of the borehole, clamp the riser and allow the clamp to rest on the borehole.

Use the tripod or crane to lift the pump out of the borehole.

Please note. If the Boreline and pump have to be removed while full of water the column will be heavier than normal. In this case make sure to provide for the extra weight when using lifting devices and vehicles.

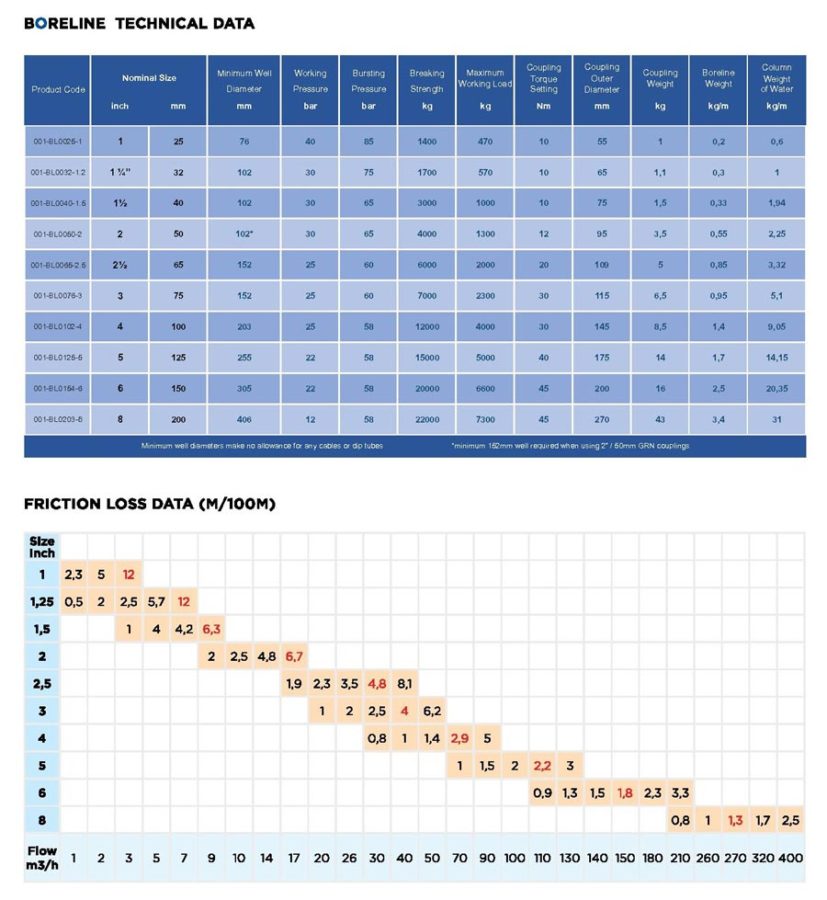

See full specification table for the nominal weights of the Boreline and water column per metre/foot. Please note that the weights of the pump, cable and accessories should be added to establish the total weight of the column.

Break-Off Plug / Drainer System ( 2” and above )

Break-Off Plug / Drainer System ( 2” and above ) The Break-Off System has been developed to avoid this : the non-return valve is retained intact and a hollow stainless steel drainer plug is fitted across the lower Boreline coupling. This is then broken off at a weak point, when necessary, with a special ‘torpedo’ lowered down the hose.

The Break-Off System has been developed to avoid this : the non-return valve is retained intact and a hollow stainless steel drainer plug is fitted across the lower Boreline coupling. This is then broken off at a weak point, when necessary, with a special ‘torpedo’ lowered down the hose. The Boreline lifting clamps are required to hold the Boreline during installation and removal. The have been designed and tested by Hose Manufacturers for use on the Boreline. Two clamps are required for each installation. They are available in three sizes to suit the whole Boreline Range. From 1” to 8”. Boreline Clamp Light Duty LC1 : 1″ to 2″ Boreline Clamp Medium Duty LC2: 2″ to 5″ Boreline Clamp Heavy Duty LC3: 6″ to 8″. Special clamps can be designed and manufactured on request.

The Boreline lifting clamps are required to hold the Boreline during installation and removal. The have been designed and tested by Hose Manufacturers for use on the Boreline. Two clamps are required for each installation. They are available in three sizes to suit the whole Boreline Range. From 1” to 8”. Boreline Clamp Light Duty LC1 : 1″ to 2″ Boreline Clamp Medium Duty LC2: 2″ to 5″ Boreline Clamp Heavy Duty LC3: 6″ to 8″. Special clamps can be designed and manufactured on request. A tripod or crane will be required to lift the pump into the borehole. If a tripod is used it should be positioned directly above the borehole high enough to allow the pump and clamp to be raised into the borehole.

A tripod or crane will be required to lift the pump into the borehole. If a tripod is used it should be positioned directly above the borehole high enough to allow the pump and clamp to be raised into the borehole.

Reviews

There are no reviews yet.